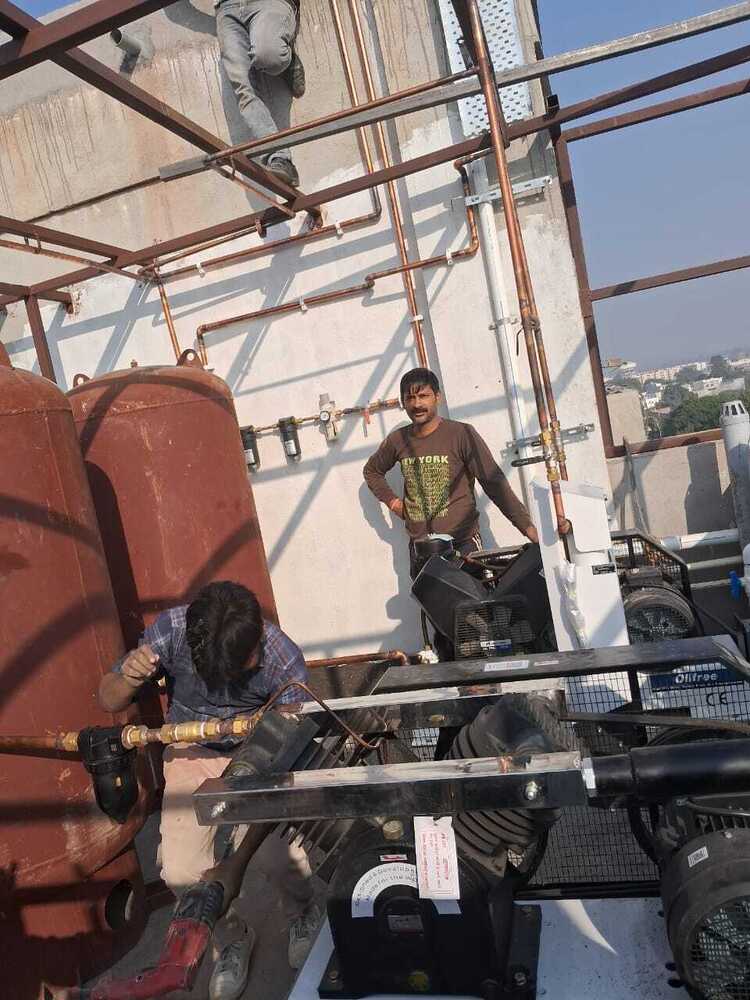

Hospital Gas Pipeline Installation

Hospital Gas Pipeline Installation Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 5000 Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About Hospital Gas Pipeline Installation

1. Design and Planning

- Pipeline Sizing: Designed to meet the specific gas flow requirements of the facility.

- Material: Typically, copper pipes (Type L or K) are used for medical gas pipelines.

- Compliance: Adheres to international standards like NFPA 99 (National Fire Protection Association), HTM 02-01, and other relevant ISO standards.

- Layouts and Blueprints: Detailed design drawings for medical gas pipelines are prepared in advance, showing location, dimensions, and sizing.

2. Components for Installation

- Medical Gas Outlets: Specific outlets per gas type (Oxygen, Nitrous Oxide, Medical Air, Vacuum, etc.).

- MAP Company outlets typically feature color-coded and key-coded designs for safety and easy identification.

- Zonel Valves: Enables isolation of specific zones or sections in emergencies.

- Designed for easy access, usually installed at prominent, accessible points.

- Alarm Systems: Monitors pipeline pressure and alerts for any irregularities.

- Manifold Systems: Controls gas supply and ensures uninterrupted delivery.

- Control Panels: Centralized control over multiple gases for ease of operation.

- Pressure Regulators and Gauges: Ensures the gas is supplied at consistent, regulated pressure.

3. Installation Process

- Piping: Pipes are brazed using high-quality filler metals to prevent leaks and corrosion.

- Purging: The system is purged using Nitrogen to prevent contamination and oxidation during brazing.

- Labeling: Gas lines are color-coded and labeled per gas type along their length.

- Connections: Flanged, quick-connect, or threaded connections as per design.

4. Testing Procedures

- Pressure Testing: Tests for leakages by pressurizing the system with an inert gas (often Nitrogen).

- Pressure Levels: Typically 1.5 times the working pressure.

- Leak Testing: Vacuum is applied to the system and checked for any pressure drop over a set period.

- Purity Testing: Ensures that the pipeline is free from contaminants before first use.

5. Commissioning and Documentation

- Flow and Pressure Verification: Confirm that gases flow at the required pressure and volume to all outlets.

- System Documentation: Includes blueprints, certificates of compliance, inspection reports, and test results.

- Staff Training: Instruct medical staff on the usage and emergency protocols associated with the gas pipeline system.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free